We get a lot of questions about our manufacturing process, what we do, when will we release a new product and, lastly, why does it seem like we out of some thing so often?

To give you a little idea, we want to share with you the story behind what it takes to create our products.

Before we start, we should emphasize we take a lot of pride and care in bringing our products to market, and we continually strive to make things of the highest quality and standards.

So, let’s begin.

The materials.

All of our rigid locking collars and necklaces are made from Titanium and building anything in this metal, especially items meant to be worn as jewelry, can be tricky.

We start by sourcing the right materials and product and making sure the consistency stays the same. We work with suppliers from around the world to source the best materials.

The making.

We will try not to bore you with the manufacturing details, so the easiest way to explain it is our rigid collars are made in batches using a rod of titanium with a cast mold and hand welding process.

Each rod is heated to a molten state using a special process and then bent around a mold to form both halves of the collar or cuff. This rough production set is then sent through a secondary process where the hinges, clasps, and details are milled to a high degree of precision.

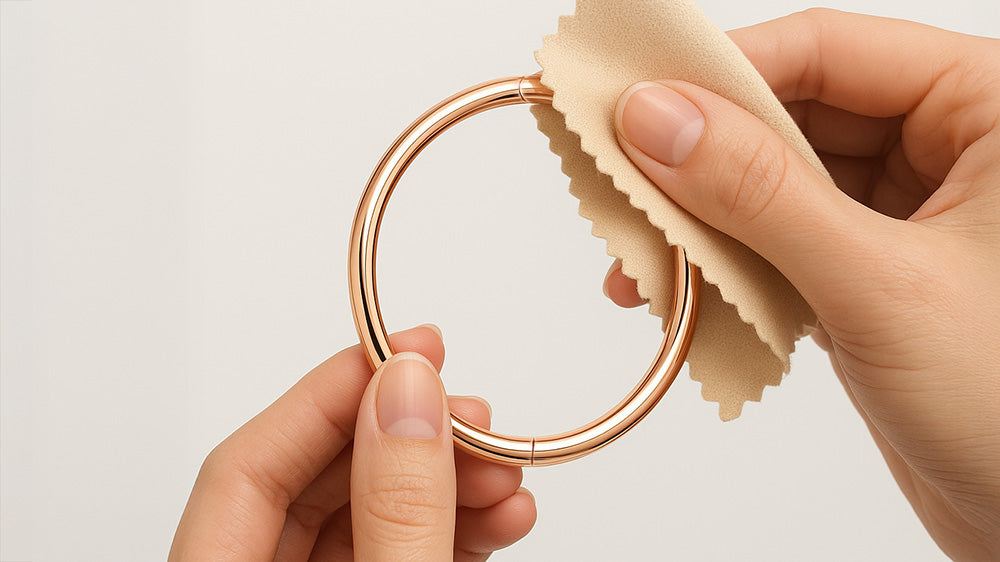

Once this is complete, the two halves are boded together with a welded hinge pin, and then sent to polishing for a mirror finish. Any items with a special finish are sent through an additional high-durability coating process.

The timing.

From the time we first decide we need to make more collars to the time it takes to make them available, we invest several months of sourcing, manufacturing and inspecting. If we have a secondary finish, like the black or gold coating, it can add another 2 to 6 weeks to that timeframe.

So why do we sometimes not have a specific product or size in stock?

We work really hard to make sure we have everything listed on our site in stock. But, it is not always easy.

When you combine the way we source materials and the way we manage our production, a couple of things can impact availability.

For example, if we receive a supply of raw titanium but receive the wrong grade, we might be delayed waiting for the correct supply. Or, if we have a mistake in a batch, such as the hinge-pin not welding in place properly, we have to start all over and run a new batch.

Hopefully this gives you a little insight into our process for making our rigid collars. As always, we want to hear from you if you have any questions or suggestions.